R-5680

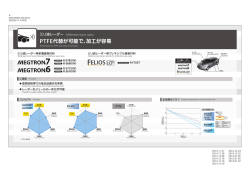

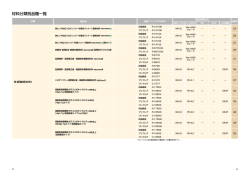

High speed transmission For ICT infrastructure equipment 低誘電率・低誘電正接・高耐熱多層基板材料(低誘電ガラスクロス仕様) Low Dk . Low Df and High Tg for Multi-layer Circuit Board Materials MEGTRON 7 (Low-dielectric glass cloth specification) Prepreg Laminate R-5785 R-5680 MEGTRON6 の 1/2 の Df 値を実現。 業界最高の低伝送損失で、次世代 ICT 機器の高速伝送に貢献。 Realize 1/2, Df (dissipation factor) MEGTRON6. Contributing to the high-speed transmission of next generation ICT infrastructure equipment by low transmission loss of the industry's highest. 特長 /Features 1. Ultra-low transmission loss Low dielectric constant (Dk) 3.3(1GHz), 3.3(12GHz) Low dissipation factor (Df) 0.001(1GHz), 0.002(12GHz) (1/2 of MEGTRON6) 2. High heat resistance and reliability (equivalent to MEGTRON6) 3. Compatible with lead-free soldering ①超低伝送損失 低誘電率 Dk=3.3(1GHz), 3.3(12GHz) 低誘電正接 Df=0.001 (1GHz),0.002(12GHz) (MEGTRON6の1/2) ②優れた耐熱性と信頼性 (MEGTRON6と同等) ③鉛フリーはんだ対応 用途 /Applications High-end servers, High-end routers, Supercomputers, and other ICT infrastructure equipment ハイエンドサーバ、ハイエンドルータ、スーパーコンピュータなど ICT インフラ機器 誘電特性 Dielectric property (E-glass) 3.6 3.4 (E-glass) 3.2 0.004 (E-glass) 0.002 (LowDK-glass) Transmission loss (dB/m) 伝送損失 3.8 (LowDK-glass) 3.0 0 5 10 15 20 周波数 Frequency [GHz] 25 30 0.000 0 5 10 15 20 絶縁抵抗値 Insulation resistivity(Ω) -30 -50 (E-glass) 0 1.0E+11 5 10 15 周波数 Frequency (GHz) 1.0E+10 1.0E+09 T288 1.0E+08 熱膨張係数 (タテ方向) CTE (α1) x-axis 1.0E+07 1.0E+06 熱膨張係数 (ヨコ方向) CTE (α1) y-axis 1.0E+05 評価サンプル Evaluation sample 0.35mm 1.6mm 400 1000 評価条件 Evaluation condition スルーホール径 0.35mm Through-hole diameter スルーホール壁間距離 Through-hole wall to wall distance t 20 一般特性 General properties 熱分解温度 Thermal decomposition temp (Td) 200 300 処理時間 Time (Hrs) w 回路幅 (w) 0.1mm Trace width (w) 回路厚み (t) 0.035mm Trace thickness (t) 絶縁層厚み (h) 0.30mm Dielectric thickness (h) (LowDK-glass) -40 ガラス転移温度 Glass transition temp (Tg) 100 h -20 評価項目 Item 1.0E+12 0 (LowDK-glass) (E-glass) -10 25 30 周波数 Frequency [GHz] 耐CAF性(実測値) CAF resistance 1.0E+04 評価サンプル Evaluation sample 0 (E-glass) 誘電正接 Dissipation factor (Df) 比誘電率 Dielectric constant (Dk) 伝送損失比較 Frequency dependence of transmission loss 0.006 4.0 0.35mm 温度 Temperature 121℃ 湿度 Humidity 85% 印加電圧 Voltage 50V 試験方法 Test method 条件 Condition 単位 Unit DSC As received TG/DTA R-5785 R-5775 Low Dk-glass E-glass E-glass ℃ 200 200 185 As received ℃ 400 400 410 IPC TM-650 2.4.24.1 As received min >120 >120 >120 IPC TM-650 2.4.41 below Tg 14-16 14-16 14-16 14-16 14-16 14-16 42 42 45 280 280 260 ppm/℃ below Tg 熱膨張係数 (厚さ方向) CTE (α1) z-axis IPC TM-650 2.4.24 比誘電率 Dielectric constant (Dk) IPC TM-650 2.5.5.9 C-24/23/50 @1GHz 3.3 3.6 3.7 誘電正接 Dissipation factor (Df) IPC TM-650 2.5.5.9 C-24/23/50 @1GHz 0.001 0.0015 0.002 吸水率 Water absorption IPC TM-650 2.6.2.1 D-24/23 % 0.06 0.06 0.14 JIS C6481 As received GPa 18 19 19 IPC TM-650 2.4.8 As received kN/m 1.2 1.2 1.2 曲げ弾性率 Flexural modulus (Weft) 銅箔引き剥がし強さ Peel strength 1 oz (35μm) above Tg 試験片の厚さは0.8mmです。 The sample thickness is 0.8mm ◎ 上記データは弊社での実測値であり、保証値ではありません。 The above data is actual values and not guaranteed values. Circuit Board Materials | June 2014 | 4

© Copyright 2026