37th Asia Expert Meeting on UN Regulations Related to Electric

37th Asia Expert Meeting on UN Regulations Related to Electric Vehicle

Measurement of Net Power (R85),

Requirement for Frontal Crash Regulation (R94),

Requirement for Side Impact Regulation (R95),

Requirement for the Electric Power Train (R100)

Date

Place

:

:

August 6th, 2014 (WED)

Pullman King Power Hotel, Bangkok

http://www.pullmanbangkokkingpower.com/

8:30 - 9:30

Registration

9:30 - 9:40

Opening Address : from DLT

9:40 – 9:45

Message : from JASIC

9:45 - 10:00

Photo Session

10:00 - 10:20

Coffee Break (20 minutes)

10:20 - 11:20

R94 & R95 & R100 General Information, Technical Requirements

Information for the following items requested by DLT

Periodic inspection for electric vehicle (checklists or additional check items)

Rescue on electric vehicle in case of emergency e.g. crashing and flood

Daily maintenance for electric vehicle

: from Mr. Okura

Q & A & Discussion

11:30 - 13:00

Lunch

13:00 - 14:00

R94 & R95 & R100 Testing

: from Mr. Sawamura

Q & A & Discussion

14:00 - 14:20

Coffee Break (20 minutes)

14:20 - 15:20

R85 General Information, Technical Requirements & Testing

: from Mr. Yamanaka

Q & A & Discussion

15:20 - 15:40

Closing address : from DLT

R100, R12, R94, R95

General Information

- Technical Requirements August 6, 2014

JASIC

Kazuma OKURA

Contents

- Overview of R100, R12, R94, R95

- Technical Requirements

1. In-use Safety(R100 Part Ⅰ)

a. Protection against Electrical Shock

b. Functional Safety

2. Post-crash Safety(R12, R94, R95)

a. Protection against Electrical Shock

b. REESS Requirements

3. REESS Safety(R100 Part Ⅱ)

- Vehicle Inspection

- Rescue Manual

Overview of R100, R12, R94, R95

Japanese

Regulation

History

UN R

WP29

1997

R100-00

2007

Approval of ELSA

Attachment1102)

ELSA1)

Main Issue : Electrical Shock

Attachment1113)

In-Use Discussion

Post-Crash Discussion

2010 R100-01

R100-01(Part Ⅰ)

2011 R12-04

R94-02

R95-03

R12-04

R94-02

R95-03

2013 R100-02

R100-02(Part Ⅱ)

1)

2)

3)

Main Issue : Battery

Informal Group on Electric Safety

Technical Standard for Protection of Occupants

against High Voltage in Electric Vehicles and Hybrid Electric Vehicles

Technical Standard for Protection of Occupants against High Voltage

after Collision in Electric Vehicles and Hybrid Electric Vehicles

Overview of R100, R12, R94, R95

Scope

UN R

Scope

R100 Series 01

Safety requirements with respect to the

electric power train of road vehicles

R100 Series 02

Part Ⅱ

Safety requirements with respect to the

Rechargeable Energy Storage

System(REESS) of road vehicles

R12

Series 04

Safety Requirements with respect to the

electric power train of road vehicles

after full-wrap frontal collision(5.5)

R94

Series 02

Safety Requirements with respect to the

electric power train of road vehicles

after frontal offset collision(5.2.8)

R95

Series 03

Safety Requirements with respect to the

electric power train of road vehicles

after lateral collision(5.3.7)

Comments

Dedicated to EV,

HEV, and FCV

Post-crash

safety regulations

applied to all the

vehicles

Additional

requirements

dedicated to EV,

HEV, and FCV

Overview of R100, R12, R94, R95

Objective Parts

High Voltage Cables

High Voltage

↓

> 60 Vdc

or

> 30 Vac

Integrated Box

- On-board Charger

- DC/DC Converter

Inverter

High Voltage Battery

Charging Inlets

- Normal

- Quick

Other High Voltage Components

- Air Compressor for HVAC

- PTC Heater

Traction Motor

Overview of R100, R12, R94, R95

Basic concept for the Protection against Electrical Shock

Electrical Shock :

The passage of an electric current through the human body by direct

contact or indirect contact with 2 points which have different electric

potential(voltage)

Direct Contact :

The contact of persons with live parts(the conductive parts intended to be

electrically energized in normal use

Indirect Contact :

The contact of persons with exposed conductive parts

+

+

+

+

-

-

-

-

Direct Contact

Indirect Contact

Overview of R100, R12, R94, R95

Basic Concept for the Protection against Electrical Shock

(1) Protection

against direct contact

with live parts of the

powertrain

(2)Protection against

indirect contacts with

exposed conductive

parts of the

powertrain

Prevention by insulation

and/or by the use of barriers,

enclosures, or others

Ensure occupant

safety by 3

approaches (3) Maintenance of 500Ω/Volt

or higher insulation resistance

Potential equalization resistance

between exposed conductive parts

and electrical chassis be below 0.1.

Minimum insulation resistance of

500/volt, which eliminates occupant

harming risks. Insulation resistance will be

harmonized with related standards based

on the latest studies.

R100 Part Ⅰ Technical Requirements

1. Protection against Electrical Shock

Protection against Direct Contact

<Requirement>

The protection against direct contact with live parts1) shall comply with

- IPXXD2) inside the passenger compartment or luggage compartment and

- IPXXB3) in areas other than the passenger compartment or luggage compartment.

These protections (solid insulator, barrier, enclosure, etc.) shall

not be able to be opened, disassembled or removed without the use of tools.

1)

2)

live parts : the conductive parts intended to be electrically energized in normal use.

IPXXB, IPXXD : protection degrees

<Purpose>

to prevent human body from touching “high voltage”.

<Measures>

barrier, enclosure : ex. aluminum casting case etc.

exception : connector, service disconnect

R100 Part Ⅰ Technical Requirements

1. Protection against Electrical Shock

Protection against Direct Contact

the passenger compartment

or luggage compartment

IPXXB – 80mm standard

finger cannot touch live parts

(5.1.1.3)

IPXXD –100mm wire cannot

touch live parts (5.1.1.1)

IPXXB – 80mm standard finger cannot

touch live parts (5.1.1.2)

Connectors

(including vehicle inlet)

areas other than

the passenger compartment

or luggage compartment

R100 Part Ⅰ Technical Requirements

1. Protection against Electrical Shock

Protection against Direct Contact

<Requirement>

The symbol shall appear on or near the REESS. The symbol background shall

be yellow, the bordering and the arrow shall be black.

The symbol shall also be visible on enclosures and barriers,

which, when removed expose live parts of high voltage circuits.

This provision is optional to any connector for high voltage buses.

This provision shall not apply to any of the following cases:

(a)Where barriers or enclosures cannot be physically accessed, opened, or

removed; unless other vehicle components are removed with the use of tools;

(b) Where barriers or enclosures are located underneath the vehicle floor.

Cables for high voltage buses which are not located within enclosures shall

be identified by having an outer covering with the colour orange.

<Purpose>

to prevent users from opening, disassembling, removing unconsciously.

R100 Part Ⅰ Technical Requirements

1. Protection against Electrical Shock

Protection against Direct Contact

EUR/US

RUSSIA

ARABIA

ASIA

R100 Part Ⅰ Technical Requirements

1. Protection against Electrical Shock

Protection against Indirect Contact

<Requirement>

For protection against electrical shock which could arise from indirect contact,

the exposed conductive parts, such as the conductive barrier and enclosure,

shall be galvanically connected securely to the electrical chassis by

connection with electrical wire or ground cable, or by welding, or by

connection using bolts, etc. so that no dangerous potentials are produced.

The resistance between all exposed conductive parts and the electrical

chassis shall be lower than 0.1 ohm when there is current flow of at least

0.2 amperes.

This requirement is satisfied if the galvanic connection has been established

by welding.

<Purpose>

to prevent human body from getting an electric shock even if isolation

resistance between the live parts and the exposed conductive parts

decreases.

R100 Part Ⅰ Technical Requirements

1. Protection against Electrical Shock

Protection against Indirect Contact

<Requirement>

In the case of motor vehicles which are intended to be connected to the

grounded external electric power supply through the conductive connection,

a device to enable the galvanical connection of the electrical chassis to the

earth ground shall be provided.

The device should enable connection to the earth ground before exterior

voltage is applied to the vehicle and retain the connection until after the

exterior voltage is removed from the vehicle.

Compliance to this requirement may be demonstrated either by using the

connector specified by the car manufacturer, or by analysis.

<Background>

The grounding of the electrical chassis of the vehicle lowers the risk of the

electrical shock during the charging.

R100 Part Ⅰ Technical Requirements

1. Protection against Electrical Shock

Isolation Resistance

<Requirement>

If AC high voltage buses and DC high voltage buses are galvanically isolated

from each other, isolation resistance between the high voltage bus and the

electrical chassis shall have a minimum value of 100 ohms/volt of the

working voltage for DC buses, and a minimum value of 500 ohms/volt of the

working voltage for AC buses.

<Purpose>

simultaneously

to prevent arespectively

leak current from passing through the

human body.

※ sufficiently lower than the internal resistance of the human body

AC≧500Ω/V

Motor

DC≧100Ω/V

Inverter

Isolated

Battery

AC+DC≧500Ω/V

Motor

Inverter

Non-isolated

Battery

R100 Part Ⅰ Technical Requirements

1. Protection against Electrical Shock

Isolation Resistance

<Exception for Fuel cell vehicles>

If the minimum isolation resistance requirement cannot be maintained over

time, then protection shall be achieved by any of the following:

(a) Double or more layers of solid insulators, barriers or enclosures that

meet the requirement in paragraph 5.1.1. independently;

(b) On-board isolation resistance monitoring system together with a warning

to the driver if the isolation resistance drops below the minimum required

value.

<Reason>

difficult to keep isolation resistance of FCVs

R100 Part Ⅰ Technical Requirements

1. Protection against Electrical Shock

Isolation Resistance

<Requirement>

For the vehicle inlet intended to be conductively connected to the grounded

external AC power supply and the electrical circuit that is galvanically

connected to the vehicle inlet during charging of the REESS, the isolation

resistance between the high voltage bus and the electrical chassis shall be at

least 1 megohm when the charger coupler is disconnected. During the

measurement, the traction battery may be disconnected.

<Reason>

Same as IEC requirement.

electrical circuit

≧1MΩ

Charger

REESS

vehicle inlet

to the grounded

external AC

power supply

R100 Part Ⅰ Technical Requirements

2. Functional Safety

Indicator for “Ready to Run”

<Requirement>

At least a momentary indication shall be given to the driver when the vehicle is

in "active driving possible mode".

However, this provision does not apply under conditions where an internal

combustion engine provides directly or indirectly the vehicle's propulsion

power.

When leaving the vehicle, the driver shall be informed by a signal (e.g. optical

or audible signal) if the vehicle is still in the active driving possible mode.

<Background>

This requirement follows the provision in R100-00, but the exemption is added

in consideration of hybrid vehicles.

R100 Part Ⅰ Technical Requirements

3. Functional Safety

Prevention against Vehicle Movement with Charging Connection

<Requirement>

If the on-board REESS can be externally charged by the user, vehicle

movement by its own propulsion system shall be impossible as long as the

connector of the external electric power supply is physically connected to the

vehicle inlet.

This requirement shall be demonstrated by using the connector specified by

the car manufacturer.

<Purpose>

To prevent a vehicle from tearing off the charging cable.

R100 Part Ⅰ Technical Requirements

3. Functional Safety

Indicator of the drive direction

<Requirement >

The state of the drive direction control unit shall be identified to the driver.

<Background>

Electric vehicles normally control the drive direction only by the traction

motor control, not by mechanical devices such as reverse gear .

R12, R94, R95 Technical Requirements

Background

R100 requires not to get an electrical shock even if one failure occurs.

※ For example, if the insulation resistance becomes low, but the

potential equalization still comply with the indirect contact requirement,

there are no risks of having the electrical shock.

This technical regulation aims to provide the requirements for post-crash

safety, then it considers minimum requirements for the protection of

occupants of a vehicle.

The condition of the electrical shock includes not only the direct contact,

the indirect contact, the insulation resistance, but also the voltage and

the energy of the electrical shock circuit.

R12, R94, R95 Technical Requirements

1. Protection against Electrical Shock

<Requirement>

After the impact at least one of the four criteria specified

1. Absence of high voltage

2. Low electrical energy

3. Physical protection

4. Isolation resistance

<Background>

Explained in the previous slide.

R12, R94, R95 Technical Requirements

2. REESS Requirements

Electrolyte Spillage

<Requirement>

In the period from the impact until 30 minutes after no electrolyte from the

REESS shall spill into the passenger compartment and no more than 7 per

cent of electrolyte shall spill from the REESS except open type traction

batteries outside the passenger compartment. For open type traction

Batteries no more than 7 per cent with a maximum of 5.0 liters shall spill

outside the passenger compartment.

<Purpose>

to prevent electrolyte from catching fire.

R12, R94, R95 Technical Requirements

2. REESS Requirements

REESS Retention

<Requirement>

REESS located inside the passenger compartment shall remain in the location

in which they are installed and REESS components shall remain inside

REESS boundaries.

No part of any REESS that is located outside the passenger compartment for

electric safety assessment shall enter the passenger compartment during or

after the impact test.

<Purpose>

to prevent persons from getting hurt by REESS.

R100 Part Ⅱ

The Structural Feature of the Regulation

Technical Requirements

Part Ⅰ : Vehicle requirements regarding the electrical safety

(= the requirements of R100-01)

Part Ⅱ : Safety requirements for REESS

(= the requirements added in R100-02)

Approval Provisions

Part 1 : Vehicle type approval including REESS

Part 2 : REESS type approval

R100 Part Ⅱ

The Selection of Test Method (Vehicle / Component)

At the manufacturer's choice the test may be performed as

(a) Vehicle based tests

or

(b) Component based tests

<Background>

Vehicle manufacturers can secure the REESS safety

by whole vehicle(the control system, vehicle body structure).

It is difficult for some of REESS suppliers

to test the REESS system as a part of vehicle.

R100 Part Ⅱ

Nissan LEAF Battery Layout & Structure

Chassis

Battery

Pack

Battery management system

Junction box

include

Service disconnect SW

Module

48 modules / Vehicle

Cell

192 cells / Vehicle

4 cells / Module

R100 Part Ⅱ

Battery Management System(BMS)

SOC

SOH

Operational Limit

Diagnosis

R100 Part Ⅱ Technical Requirements

1. Vibration(Component Based Test)

2.

3.

4.

5.

6.

7.

8.

9.

10.

to verify the safety performance of the REESS under a vibration environment during the

normal operation of the vehicle.

Thermal Shock and Thermal Cycling(Component Based Test)

to verify the resistance of the REESS to sudden changes in temperature.

Mechanical Shock(Vehicle Based Test(R12, R94, R95) or Component Based Test)

to verify the safety performance of the REESS during a vehicle crash.

Mechanical Integrity(Vehicle Based Test(R12, R94, R95) or Component Based Test)

to verify the safety performance of the REESS during vehicle crash situation.

Fire Resistance(Vehicle Based Test or Component Based Test)

to verify the resistance of the REESS, against exposure to fire from outside of the vehicle.

External Short Circuit Protection(Component Based Test)

to verify the performance of the short circuit protection.

Overcharge Protection(Component Based Test)

to verify the performance of the overcharge protection.

Over-discharge Protection(Component Based Test)

to verify the performance of the over-discharge protection.

Over-temperature Protection(Component Based Test)

to verify the performance of the protection measures of the REESS against internal

overheating during the operation

Emission(No need for Lithium ion battery)

Vehicle Inspection

Announcement that Prescribes Details of Safety Regulations

for Road Vehicles, Article 177

Solid insulators, barriers, enclosures, etc. which are mounted on energized

components in order to protect against contact of the human body with the

energized components of the power train shall exhibit no looseness or damage

liable to hamper their functions.

The barrier and enclosure protecting the energized components of the power

train shall be marked in accordance with the example given in the technical

requirements of Agreement Regulation No. 100.

The cables of the energized components of the power train used in the highvoltage buses (except cables for high voltage buses which are located within

enclosures) shall be identified from other electric cables by having an outer

covering with the colour orange.

Vehicle Inspection

Announcement that Prescribes Details of Safety Regulations

for Road Vehicles, Article 177

Solid insulators, barriers, enclosures, etc. which are mounted on energized

components in order to protect against contact of the human body with the

Visual

Inspection

energized components of

the power

train shall exhibit no looseness or damage

liable to hamper their functions.

The barrier and enclosure protecting the energized components of the power

train shall be marked in Visual

accordance

with the example given in the technical

Inspection

requirements of Agreement Regulation No. 100.

The cables of the energized components of the power train used in the highvoltage buses (except cables

high voltage buses which are located within

VisualforInspection

enclosures) shall be identified from other electric cables by having an outer

covering with the colour orange.

Vehicle Inspection

Announcement that Prescribes Details of Safety Regulations

for Road Vehicles, Article 177

The insulation resistance between the energized components and the electrical

chassis shall be monitored. In the case of motor vehicles equipped with a function

whereby a warning is given to the driver before the insulation resistance drops

below 100 ohms per volt of the operating voltage, the said function shall function

normally and the said device shall be in a condition that no warning is given.

As regards energized components, the fuses, circuit breakers, etc. which shut off

the electrical circuit, which are provided to prevent fire due to excessive current at

the time of failure of short circuit in the electrical circuit between the battery for

motor and the equipment connected to the said battery, shall exhibit no looseness

or damage liable to hamper their functions.

The connection with electrical wire or ground cable, welding and tightening

condition of bolts, etc., which are used to connect the exposed electroconductive

components, such as the electroconductive barrier and enclosure, to the electrical

chassis in electrical DC for the purpose of protection against electrical shock which

could arise from contact of the human body with the electroconductive barrier,

enclosure, etc., shall exhibit no looseness or damage liable to hamper their

functions.

Vehicle Inspection

Announcement that Prescribes Details of Safety Regulations

for Road Vehicles, Article 177

The insulation resistance between the energized components and the electrical

chassis shall be monitored. In the case of motor vehicles equipped with a function

Visual

Inspection

whereby a warning is given

to the

driver before the insulation resistance drops

below 100 ohms per volt of the operating voltage, the said function shall function

normally and the said device shall be in a condition that no warning is given.

As regards energized components, the fuses, circuit breakers, etc. which shut off

the electrical circuit, which are provided to prevent fire due to excessive current at

the time of failure of short

circuitInspection

in the electrical circuit between the battery for

Visual

motor and the equipment connected to the said battery, shall exhibit no looseness

or damage liable to hamper their functions.

The connection with electrical wire or ground cable, welding and tightening

condition of bolts, etc., which are used to connect the exposed electroconductive

components, such as the electroconductive barrier and enclosure, to the electrical

Inspection

chassis in electrical DC Visual

for the purpose

of protection against electrical shock which

could arise from contact of the human body with the electroconductive barrier,

enclosure, etc., shall exhibit no looseness or damage liable to hamper their

functions.

Vehicle Inspection

Announcement that Prescribes Details of Safety Regulations

for Road Vehicles, Article 177

The protection of energized components of the charging system coupling system

shall exhibit no looseness or damage liable to hamper their functions.

The device provided for connection with the grounded external power supply shall

be capable of connecting the electrical chassis to the ground in electrical DC.

A device shall be mounted for indicating to the driver that the shift position of the

transmission has been changed with the motor vehicle in a stationary state and the

motor vehicle is ready for running through the operation of the accelerator and

release of the brake system or that the motor vehicle is ready for running through

the operation of the accelerator and release of the brake system without changing

the shift position of the transmission.

Batteries for motor shall be installed securely so that they may not move or be

damaged due to vibrations, etc. of the motor vehicle.

Vehicle Inspection

Announcement that Prescribes Details of Safety Regulations

for Road Vehicles, Article 177

The protection of energized components of the charging system coupling system

Visual

Inspection

shall exhibit no looseness

or damage

liable to hamper their functions.

The device provided for connection with the grounded external power supply shall

Tester

Checkchassis to the ground in electrical DC.

be capable of connecting

the electrical

A device shall be mounted for indicating to the driver that the shift position of the

transmission has been changed with the motor vehicle in a stationary state and the

motor vehicle is ready for running through the operation of the accelerator and

Visual

Inspection

release of the brake system

or that

the motor vehicle is ready for running through

the operation of the accelerator and release of the brake system without changing

the shift position of the transmission.

Batteries for motor shall be installed securely so that they may not move or be

Visual

Inspection

damaged due to vibrations,

etc. of

the motor vehicle.

Rescue Manual

Layout of High Voltage Components

Rescue Manual

How to shut off the high voltage system

Important points when touching the high voltage components

Rescue Manual

Emergency Response Step

Rescue Manual

Safety Tools

Rescue Manual

Inspection of Safety Tools

Thank you for your patience!

UN-R100 UN-R94, 95

(ELECTRIC POWER TRAIN)

Test Procedure

National Traffic Safety and Environment Laboratory

Takashi Sawamura

August 6, 2014

1

Outline

1. Introduction

2. How to Test ?

-R100

PartⅠ

PartⅡ

-R94, R95

3. Summary

National Traffic Safety and Environment Laboratory

2

Introduction

There is an increasing number of hybrid and

electric vehicles in the world, and the trend will

continue to grow.

HV

EV

National Traffic Safety and Environment Laboratory

3

Introduction

Drivers and passengers are at risk of touching

high voltage device in vehicles.

Regulation

R100

-

R94

Frontal 56km/h

(offset)

R95

Test condition

Normal use

After Crash

Side 50km/h

National Traffic Safety and Environment Laboratory

4

How to Test?

R100

National Traffic Safety and Environment Laboratory

5

Scope

Part Ⅰ

Electric power train of road vehicles

M and N category

(Category M - Power-driven vehicles having at least four wheels and

used for the carriage of passengers, )

(Category N - Power-driven vehicles having at least four wheels and

used for the carriage of goods )

Maximum design speed exceeding 25 km/h

Equipped with one or more traction motor(s) operated by electric power

Not permanently connected to the grid, as well as their high voltage

components

Systems which are galvanically connected to the high voltage bus of the

electric power train.

Part Ⅱ

The Rechargeable Energy Storage System (REESS), of road

vehicles of categories M and N

National Traffic Safety and Environment Laboratory

6

Same Vehicle?

Test

vehicle

Compare hybrid system

Power control unit

Application

document

Motor

Battery

National Traffic Safety and Environment Laboratory

7

Requirements

5.1.Protection against electrical shock (Part I)

5.2.Rechargeable Energy Storage System (Part II)

(REESS)

5.3. Functional safety

National Traffic Safety and Environment Laboratory

8

How to Check?

5.1. Protection against electrical shock (PartⅠ)

5.1.1 Direct contact

5.1.2 Indirect contact

5.1.3 Isolation resistance

National Traffic Safety and Environment Laboratory

9

5.1.1 Protection against direct contact

Inside or luggage

IPXXD

Live parts

No contact

allowed

IPXXB

Outside

(Bonnet etc.)

Warning label required

outer covering (Cables for high voltage)

with the colour orange.

National Traffic Safety and Environment Laboratory

10

For Safety Test

Rubber glove

Protective

equipments

IPXXB (Finger model)

IPXXD (Wire model)

SIDE

TOP

National Traffic Safety and Environment Laboratory

11

Protection against direct contact

5.1.1.1.

For protection of live parts

inside the passenger compartment or luggage compartment,

the protection degree IPXXD shall be provided.

Remove the parts

without tools

IPXXD

passenger

compartment

Luggage

compartment

National Traffic Safety and Environment Laboratory

12

Protection against direct contact

5.1.1.2.

For protection of live parts

in areas other than the passenger compartment or luggage compartment,

the protection degree IPXXB shall be satisfied.

IPXXB

Bonnet parts

National Traffic Safety and Environment Laboratory

13

Protection against direct contact

5.1.1.3. Connectors

(a) They comply with 5.1.1.1. and 5.1.1.2. when separated without

the use of tools, or

(b) They are located underneath the floor and are provided with a

locking mechanism, or

(c) They are provided with a locking mechanism and other

components shall be removed with the use of tools in order to

separate the connector, or

(d) The voltage of the live parts becomes equal or below DC 60V or

equal or below AC 30V (rms) within one second after the

connector is separated.

National Traffic Safety and Environment Laboratory

14

Protection against direct contact

5.1.1.4. Service disconnect

For a service disconnect which can be opened, disassembled or removed

without tools, it is acceptable if protection degree IPXXB is satisfied under

a condition where it is opened, disassembled or removed without tools.

Can you remove it without tools?

Yes

Service

disconnect

cover

No

Service plug

Yes

Requirement

IPXXB

No

No Requirement

Disconnect

National Traffic Safety and Environment Laboratory

15

Protection against direct contact

5.1.1.5.Marking

5.1.1.5.1.

The symbol shown right figure shall appear on or near the RESS.

The symbol background shall be yellow, the bordering and the arrow

shall be black.

5.1.1.5.2.

The symbol shall also be visible on enclosures and barriers, which,

when removed expose live parts of high voltage circuits. This provision is

optional to any connector for high voltage buses. This provision shall not apply

to any of the following cases:

Battery

Disconnect

Bonnet parts

National Traffic Safety and Environment Laboratory

16

Protection against direct contact

5.1.1.5.3.

Cables for high voltage buses which are not located within enclosures

shall be identified by having an outer covering with the color orange.

Bonnet parts

National Traffic Safety and Environment Laboratory

17

How To Check?

5.1. Protection against electrical shock (Part Ⅰ)

5.1.1 Direct contact

5.1.2 Indirect contact

5.1.3 Isolation resistance

National Traffic Safety and Environment Laboratory

18

5.1.2 Protection against indirect contact

Exposed conductive parts

(Conductive cover)

Resistance must be

lower than 0.1 ohms

Electrical Chassis

National Traffic Safety and Environment Laboratory

19

Protection against indirect contact

5.1.2.1.

For protection against electrical shock which could arise from indirect contact, the

exposed conductive parts, such as the conductive barrier and enclosure, shall be

galvanically connected securely to the electrical chassis by connection with

electrical wire or ground cable, or by welding, or by connection using bolts, etc.

so that no dangerous potentials are produced.

How is it connected?

Electrical wire

Ground cable

Using bolts

Welding

National Traffic Safety and Environment Laboratory

20

Protection against indirect contact

5.1.2.2.

The resistance between all exposed conductive parts and the electrical chassis

shall be lower than 0.1 ohm when there is current flow of at least 0.2 amperes.

This requirement is satisfied if the galvanic connection has been established by welding.

Measurement example

Milliohm tester

National Traffic Safety and Environment Laboratory

21

How to Check?

5.1. Protection against electrical shock (Part Ⅰ)

5.1.1 Direct contact

5.1.2 Indirect contact

5.1.3 Isolation resistance

National Traffic Safety and Environment Laboratory

22

5.1.3 Measurement of isolation resistance

Measurement with mega-ohm tester,

or according to below method

First step

( in the case of |V1|≧|V2| )

Second step

Isonlation resistance is

1

1

Ri =

− × R0 × Vb

V '1 V1

Working voltage of 500 ohms/volt

or more required

National Traffic Safety and Environment Laboratory

23

Isolation resistance

5.1.3.

Isolation resistance

Processed wiring

ADCMT 7352A

Multi-tester

Fluke 87V

National Traffic Safety and Environment Laboratory

24

Requirements

5.1.Protection against electrical shock (Part Ⅰ)

5.2.Rechargeable Energy Storage System (Part II)

(REESS)

5.3. Functional safety

National Traffic Safety and Environment Laboratory

25

5.2.Rechargeable Energy Storage System (Part II)

(REESS)

-Vibration

-Thermal shock and cycling

-Mechanical Shock

-Mechanical Integrity

-Fire resistance

-External short circuit protection

-Overcharge protection

-Over-discharge protection

-Over-temperature protection

-Emision (Not applicable lithium-ion battery) ←Omit explanation

National Traffic Safety and Environment Laboratory

26

6.2.Vibration test

Test condition

Ambient temperature: 20±10℃

SOC: upper 50%

・Sinusoidal waveform

・Logarithmic sweep between 7 Hz

and 50 Hz in 15 minutes.

・Repeat 12 times for a total of 3 hours

・Vertical direction of the mounting

orientation of the REESS

Acceptance criteria

・No electrolyte leakage

・No fire

Acc 【m/s^2】

Test procedure

10

2

7

18

30 50

Frequency【Hz】

The correlation

between frequency and acceleration

・No rupture

・No explosion

National Traffic Safety and Environment Laboratory

27

6.3. Thermal shock and cycling

Test condition

Test procedure

・60 ± 2℃ (At least six hours)

・60 ℃ ⇒ - 40℃ (Within 30 min)

・- 40± 2℃ (At least six hours)

・- 40 ⇒ 60 ℃ (Within 30 min)

Temperature【℃】

SOC: upper 50%

60

40

20

0

-20 0

20

40

60

80

-40

・ Repeat above 5 times

-60

・Then keep 20±10℃ 24 hours

Acceptance criteria

・No electrolyte leakage

・No fire

80

Time【hour】

・No rupture

・No explosion

National Traffic Safety and Environment Laboratory

28

6.4.1. Mechanical Shock

Choice for test

(a) Vehicle based test

(b) Component based test

(c) Any combination of (a) and (b) above

Manufacturer's choice for test

The approval of a REESS tested under (a) shall be limited to the specific

vehicle type.

National Traffic Safety and Environment Laboratory

29

6.4.1. Mechanical Shock

(a) Vehicle based test

Test condition

The ambient temperature and the SOC shall be in accordance with the said Regulations.

Test procedure

Frontal impact: Regulation No. 12 or No. 94

Side impact.: Regulation No. 95

Acceptance criteria

・ No fire ・ No explosion

National Traffic Safety and Environment Laboratory

30

6.4.1. Mechanical Shock

(b) Component based test

Test condition

Ambient temperature: 20±10℃

SOC: upper 50%

Test procedure

The tested-device shall be decelerated or accelerated in compliance with the

acceleration corridors which are specified in next page

Acceptance criteria

・No electrolyte leakage

・ No fire

・ No explosion

・The tested-device shall be retained by its mounting and its components shall

remain inside its boundaries.

・The isolation resistance shall ensure at least 100 Ω/Volt or the

protection degree IPXXB shall be fulfilled for the tested-device.

National Traffic Safety and Environment Laboratory

31

Longitudinal

Transverse

M1, N1 車両進行方向

M1, N1 車両横方向

25

Acc

【G】

Acceleration [g]

M1 and N1

Acc

【G】

Acceleration [g]

30

20

15

10

5

0

0

20

40

60

80

100

120

16

14

12

10

8

6

4

2

0

0

140

20

Time [ms]

40

140

100

120

140

100

120

140

12

Acc

【G】

Acceleration [g]

Acc

【G】

Acceleration [g]

120

M2, N2 車両横方向

20

15

10

5

10

8

6

4

2

0

0

0

20

40

60

80

100

120

0

140

20

40

60

80

Time [ms]

Time【msec】

Time【msec】

Time [ms]

M3, N3 車両進行方向

M3, N3 車両横方向

14

12

12

10

Acc

【G】

Acceleration [g]

Acc

【G】

Acceleration [g]

100

Time【msec】

M2, N2 車両進行方向

M3 and N3

80

Time [ms]

Time【msec】

M2 and N2

60

10

8

6

4

2

0

8

6

4

2

0

0

20

40

60

80

100

120

140

Time【msec】

Time [ms]

0

20

40

60

80

Time [ms]

Time【msec】

National Traffic Safety and Environment Laboratory

32

6.4.2. Mechanical integrity

Choice for test

(a) Vehicle based test

(b) Component based test

Manufacturer's choice for test

(a) Vehicle based test

Choice for test

-a Dynamic test

-b Specific component test

-c Any combination of (a) and (b) above

The approval of a REESS tested under (a) Vehicle based test

shall be limited to the specific vehicle type.

National Traffic Safety and Environment Laboratory

33

6.4.2. Mechanical integrity

(a)-a Dynamic test

Test condition

The ambient temperature and the SOC shall be in accordance with the said Regulations.

Test procedure

Frontal impact: Regulation No. 12 or No. 94

Side impact.: Regulation No. 95

Acceptance criteria

・ No fire ・ No explosion

National Traffic Safety and Environment Laboratory

34

6.4.2. Mechanical integrity

(a)-b Specific component test

Test condition

Ambient temperature: 20±10℃

SOC: upper 50%

Test procedure

Load :The data obtained from either actual tests or simulation

onset time less than 3 (min) and a hold time

of at least 100 (ms) but not exceeding 10 s.,

Acceptance criteria

・ No fire ・ No explosion

・No electrolyte spillage from the REESS ( Passenger compartment)

・No more than 7% by volume of the REESS electrolyte capacity shall spill from the REESS

・For open type traction batteries a limitation to a maximum of 5L also applies

・The REESS(located inside)shall remain in the installed location,

and the REESS(located outside)shall not enter the passenger compartment

during or after the impact test procedures.

・The isolation resistance shall ensure at least 100 Ω/Volt or the protection degree

IPXXB shall be fulfilled for the tested-device.

National Traffic Safety and Environment Laboratory

35

6.4.2. Mechanical integrity

(b) Component based test

Test condition

Ambient temperature: 20±10℃

SOC: upper 50%

Test procedure

Load :100 kN~105 kN,

onset time less than 3 (min) and a hold time

of at least 100 (ms) but not exceeding 10 s.,

Acceptance criteria

・ No fire ・ No explosion

・No electrolyte spillage from the REESS ( Passenger compartment)

・No more than 7% by volume of the REESS electrolyte capacity shall spill

from the REESS

・The REESS shall remain in the installed location,

・The isolation resistance shall ensure at least 100 Ω/Volt or the protection

degree IPXXB shall be fulfilled for the tested-device.

National Traffic Safety and Environment Laboratory

36

6.5. Fire resistance

Choice for test

(a) Vehicle based test

(b) Component based test

Test condition

Ambient temperature: at least 0℃

SOC: upper 50%

Not applicable

・REESS not containing flammable electrolyte.

・Lowest surface of the casing of the REESS is more than 1.5m

above the ground

The approval of a REESS tested under (a) shall be limited to the specific

vehicle type.

National Traffic Safety and Environment Laboratory

37

Test procedure

Phase A:

Pre-heating 【60 sec】

Screen

Device under test

Phase B:

Direct exposure to flame【70 sec】

Fuel pan with

Burning fuel

Phase C:

Indirect exposure to flame【60 sec】

Phase D:

End of test

Acceptance criteria

・No explosion

National Traffic Safety and Environment Laboratory

38

6.6. External short circuit protection

Test condition

Ambient temperature: 20±10℃

SOC: upper 50%

Test procedure

not exceeding

5mΩ

・ All relevant main contactors for charging and discharging shall be closed

+

・ If this cannot be completed in a single test, then two or more tests shall be conducted.

・The connection used for produce a short circuit shall have a resistance not exceeding 5 milliohms

.

A short circuit state is held until it can check the following.

○ until the operation of the REESS‘s protection function to interrupt or limit the short circuit

current is confirmed

○ the temperature gradient varies by a less than 4℃ through 1hour.(casing of the tested-device )

REESS

-

・Directly after the termination of the short circuit a standard cycle shall be conducted,

if not inhibited by the tested-device.

The test shall end with an observation period of 1 h at the ambient temperature conditions of the test environment.

Acceptance criteria

・No rupture

・No electrolyte leakage

・No explosion

・No fire

・The isolation resistance shall ensure at least 100 Ω/Volt

National Traffic Safety and Environment Laboratory

39

6.7. Overcharge protection

Test condition

Ambient temperature: 20±10℃

Test procedure

all relevant main contactors for charging shall be closed.

The charge control limits of the test equipment shall be disabled.

+

At least 1/3×C

The tested-device shall be charged with a charge current of at least 1/3C rate

REESS

The charging shall be continued until the tested-device (automatically) interrupts

or limits the charging. If there is no such function the charging shall be continued

until the tested-device is charged to twice of its rated charge capacity.

Directly after the termination of charging a standard cycle as described in Annex 8, Appendix 1 shall be conducted,

Discharge rate: The discharge procedure including termination criteria shall be defined by the manufacturer. If not specified,

then it shall be a discharge with 1C current.

Standard charge: The charge procedure including termination criteria shall be defined by the manufacturer.

If not specified, then it shall be a charge with C/3 current.

-

Acceptance criteria

・No rupture

・No electrolyte leakage

・No explosion

・No fire

・The isolation resistance shall ensure at least 100 Ω/Volt

National Traffic Safety and Environment Laboratory

40

6.8. Over-discharge protection

Test condition

Ambient temperature: 20±10℃

Test procedure

At least 1/3×C

all relevant main contactors for charging shall be closed.

+

The tested-device shall be charged with a charge current of at least 1/3C rate

The discharging shall be continued until the tested-device (automatically) interrupts or

limits the discharging. Where an automatic interrupt function fails to operate, or if there

is no such function then the discharging shall be continued until the tested-device is

discharged to 25 per cent of its nominal voltage level.

REESS

-

Directly after the termination of charging a standard cycle as described in Annex 8, Appendix 1 shall be conducted,

Discharge rate: The discharge procedure including termination criteria shall be defined by the manufacturer. If not

specified, then it shall be a discharge with 1C current.

Standard charge: The charge procedure including termination criteria shall be defined by the manufacturer.

If not specified, then it shall be a charge with C/3 current.

Acceptance criteria

・No rupture

・No electrolyte leakage

・No explosion

・No fire

・The isolation resistance shall ensure at least 100 Ω/Volt

National Traffic Safety and Environment Laboratory

41

6.9. Over-temperature protection

Test condition

Cooling function system of REESS shall be deactivated for the test.

(REESS will remain functional without a cooling function system)

Test procedure

・Temperature shall be continuously measured inside the casing near the cell.

・The onboard sensor if existing may be used

・Repeat charge and discharge at a steady current, so that temperature inside the

REESS will rise within the range specified by the manufacturer.

・Temperature is gradually raised until it reaches the following temperature.

REESS is equipped with protective measures against internal overheating,

Yes → operational temperature threshold

No → maximum operational temperature specified by the manufacturer.

The end of test: The test will end when one of the followings is observed:

(a) The tested-device inhibits and/or limits the charge and/or discharge to prevent the

temperature increase;

(b) The temperature of the tested-device is stabilized, which means that the

temperature varies by a gradient of less than 4 deg. C through 2 hours;

(c) Acceptance criteria prescribed in paragraph 6.9.2.1. of the Regulation are not satisfied.

+

REESS

+

REESS

-

Acceptance criteria

・No rupture

・No electrolyte leakage

・No explosion

・No fire

・The isolation resistance shall ensure at least 100 Ω/Volt

National Traffic Safety and Environment Laboratory

42

Requirements

5.1.Protection against electrical shock (Part Ⅰ)

5.2.Rechargeable Energy Storage System (Part Ⅱ)

(REESS)

5.3. Functional safety

National Traffic Safety and Environment Laboratory

43

5.3.Functional safety

At least a momentary indication shall be given to the driver

when the vehicle is in "active driving possible mode".

When leaving the vehicle, the driver shall be informed by a signal

(e.g. optical or audible signal) if the vehicle is still in the active

driving possible mode.

National Traffic Safety and Environment Laboratory

44

How to Test?

R94, R95

For the protection of the occupants of vehicles

operating on electrical power high voltage

and electrolyte leakage

National Traffic Safety and Environment Laboratory

45

Scope

Regulation

R94

Frontal 56km/h

(offset)

R95

Side 50km/h

category

M1 (GVW≦2,500 kg)

M1,N1

( R point ≦700mm)

National Traffic Safety and Environment Laboratory

46

Requirements

For example R95

5.3.7.1 Protection against electrical shock

5.3.7.2 Electrolyte leakage

5.3.7.3 REESS retention

National Traffic Safety and Environment Laboratory

47

5.3.7.1 Protection against electrical shock

・Absence of high voltage

・Low electrical energy

・Physical protection

・Isolation resistance

At least one of the four criteria shall be met.

Apply to each divided circuit individually

National Traffic Safety and Environment Laboratory

48

Absence of high voltage

REESS assembly

Electrical Chassis

High voltage exists

Less than DC60V or AC30V

Vb ,V1,V2 are measured after a collision by 60 seconds from 5 seconds

National Traffic Safety and Environment Laboratory

49

Test result

Voltage【V】

V1

V2

Vb

Time【msec】

National Traffic Safety and Environment Laboratory

50

・Low electrical energy

V2

th

(a) TE = ∫ Vb × I e dt

tc

S1

less than 2J

Vb

X-capacitors

Ie

V1

(b) TE = 12 × C

Y-capacitors

(c)

Electrical Chassis

x

(d)

(

×10 −6 × Vb − 3600

2

)

less than 2J

(

(

)

1

2

TE y1 = × C y1 ×10 −6 × V1 − 3600

2

1

2

TE y 2 = × C y 2 ×10 −6 × V2 − 3600

2

)

less than 2J

Cx, Cy1, Cy2:specified by the manufacturer

National Traffic Safety and Environment Laboratory

51

・Physical protection

Protection against direct contact

Both Inside

and outside

Live parts

Proteciton against indirect contact

Exposed conductive

parts

(Conductive cover)

IPXXB

Resistance must be

lower than 0.1

ohms

Electrical Chassis

Removing all parts that can be removed

without tools after the test

・ If the vehicle is rolled over by the side collision, IPXXB is

confirmed in that state. We check IPXXB again after returning

the vehicle right side up.

National Traffic Safety and Environment Laboratory

52

・Isolation resistance

Electrical power train consisting of separate DC- or AC-buses:

→Minimum value of 100Ω/V (DC buses), 500 Ω/V (AC buses) of the

working voltage.

Electrical power train consisting of combined DC- and AC-buses

→Minimum value of 500 Ω/V of the working voltage.

National Traffic Safety and Environment Laboratory

53

5.3.7.2 Electrolyte leakage

During 30 minutes after impact test

Passenger compartment

Inside: No Electrolyte leakage

Outside :No more than 7% of electrolyte spillage

(except open type)

In addition to the above and with a maximum of

5.0L (open type REESS)

5.3.7.3 REESS retention

Located inside:remain in the location in which they are installed

Located outside:No part of any REESS shall enter the passenger

compartment during or after the impact test.

National Traffic Safety and Environment Laboratory

54

Summary

We explained how tests

for R100, R94 and R95 are conducted.

National Traffic Safety and Environment Laboratory

55

Thank you for your attention

National Traffic Safety and Environment Laboratory

56

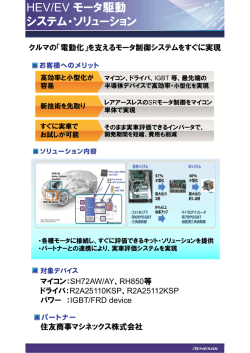

UN No.85

MEASUREMENT OF

ENGINE POWER

Aug.6.2014

JASIC

Yamanaka

1

UN No.85 MEASUREMENT OF ENGINE POWER

Both vehicle models has been approved by UN regulations

as show below.

i-MiEV

OUTLANDER plug-in hybrid EV

Front motor

Rear motor

2

UN No.85 MEASUREMENT OF ENGINE POWER

Contents

1. What’s UN No.85 ?

2. Explanation of the test equipment.

3. Explanation of the

certification test method.

3

UN No.85 MEASUREMENT OF ENGINE POWER

1. What’s UN No.85 ?

UN No.85 outline

Uniform provisions concerning the approval of internal combustion

engines or electric drive trains intended for the propulsion of motor

vehicles of categories M and N with regard to the measurement of net

power and the maximum 30 minutes power of electric drive trains.

As positioning of an organization,

It belongs in “The Working Party on Pollution and Energy” of WP29.

WP29 : World forum for harmonization of vehicle regulations.

It belongs to UN/ECE and affiliated with the committee

and the 6 working parties.

It carries out a discussion and voting of a proposed standard

which was studied technically by the working party.

4

UN No.85 MEASUREMENT OF ENGINE POWER

1. What’s UN No.85 ?

United Nations (UN)

U.N. Economic Commission for Europe

WP29

World Forum for Harmonization of Vehicle Regulations.

GRSG

GRSP

*GRPE : The Working Party on Pollution and Energy

GRPE*

GRRF

GRB

GRE

UN No.85 MEASUREMENT OF NET POWER

5

UN No.85 MEASUREMENT OF ENGINE POWER

1. What’s UN No.85 ?

About Mutual recognition

If the test of UN No.85 is certified by a country adopting the regulations,

additional certification by the other countries, joining the agreement

and applying the same regulations, is not necessary.

Individual

Recognition

Mutual

Recognition

Vehicle Manufactures

and Vehicle Parts maker

Vehicle Manufactures

and Vehicle Parts maker

Certification by

the government C

Certification by

the government A

Certification by

the government A

Certification by

the government B

market A

market B

market C

market A

market B

market C

6

UN No.85 MEASUREMENT OF ENGINE POWER

1. What’s UN No.85 ?

The countries which have adopted UN No.85

Germany, France, Italy, Netherlands, Sweden, Belgium, Hungary,

Czech Republic, Spain, Serbia, United Kingdom, Austria, Luxembourg,

Switzerland, Norway, Finland, Denmark, Romania, Poland, Portugal,

Russian Federation, Greece, Ireland, Croatia, Slovenia, Slovakia,

Belarus, Estonia, Bosnia and Herzegovina, Latvia, Bulgaria,

Lithuania, Turkey, The Former Yugoslav Republic of Macedonia, ・・・

7

UN No.85 MEASUREMENT OF ENGINE POWER

1. What’s UN No.85 ?

Contents of UN No.85

1. Scope

2. Definitions

3. Application for approval

4. Approval

5. Specifications and tests

6. Conformity of production

7. Penalties for non-conformity

8. Modification and extension of approval of the drive train type

9. Production definitely discontinued

10. Names and addresses of technical services responsible for

conducting tests, and of administrative departments

8

UN No.85 MEASUREMENT OF ENGINE POWER

1. What’s UN No.85 ?

Contents of UN No.85

ANNEXES

Annex 1 - Essential characteristics of the internal combustion engine and

information concerning the conduct of tests

Annex 2 - Essential characteristics of the electric drive train and information

concerning the conduct of tests

Annex 3 - Communication concerning the approval or extension or refusal or

withdrawal of approval or production definitely discontinued

of a drive train type pursuant to Regulation No. 85

Annex 4 - Arrangements of approval marks

Annex 5 - Method for measuring internal combustion engine net power

Annex 6 - Method for measuring net power and the maximum 30 minutes

power of electric drive trains

Annex 7 - Checks on conformity of production

9

UN No.85 MEASUREMENT OF ENGINE POWER

1. What’s UN No.85 ?

Today's candidate for explanation

This regulation is described about the power test of a internal combustion

engine and an electric motor.

Today, we focus on the electric motor, I will explain about how to test and

overview of the test.

Internal combustion engine

Electric motor

10

UN No.85 MEASUREMENT OF ENGINE POWER

2. Explanation of test equipment.

Electric motor test bench

Dynamo

Torque,

Speed

meter

Testing

Motor

11

UN No.85 MEASUREMENT OF ENGINE POWER

2. Explanation of test equipment.

The connection of the component.

Test bench

system

DC

Power source

(Input Voltage)

Wiring

Cooling system : Water

Water Pump

Voltage meter

Water hose

Dynamo

Torque/

Speed

meter

Testing

Motor

Motor

controller

Radiator

Torque request

Dynamo

control

unit

Dynamo control PC

and

Data acquisition PC

Speed request

Motor control

PC

(Commercially available

software )

12

UN No.85 MEASUREMENT OF ENGINE POWER

2. Explanation of test equipment.

Problem of the cooling system

In the bench test, the construction will be as shown when the motor is cooled

by a radiator..

However, in an actual vehicle , other components are also set in the same line.

heat up

motor

controller-A

Radiator

Water

pump

motor-A

motor

controller-B

motor-B

another

component

Coolant

water line

Bench cooling

system system

Actual vehicle cooling

system(example)

13

UN No.85 MEASUREMENT OF ENGINE POWER

2. Explanation of test equipment.

The connection of the component.

Test bench

system

DC

Power source

(Input Voltage)

Wiring

Cooling system : Oil

Voltage meter

Oil Pump

Oil hose

Water tub

Dynamo

Torque/

Speed

meter

Testing

Motor

Motor

controller

Oil cooler

Torque request

Dynamo

control

unit

Dynamo control PC

and

Data acquisition PC

Speed request

Motor control

PC

(Commercially available

software )

14

UN No.85 MEASUREMENT OF ENGINE POWER

2. Explanation of test equipment.

About cooling system.

The oil cooling system of the test bench vs the actual vehicle.

Oil temp characteristics when a

programed cycle test is carried out

on the test bench.

Example of “cycle test”.

JC-08, UN No.84, NEDC, etc.

Measurement of Fuel Consumption

Oil temp characteristics when the cycle test

is carried out by the actual vehicle.

15

UN No.85 MEASUREMENT OF ENGINE POWER

2. Explanation of test equipment.

About Auxiliaries

Auxiliaries to be fitted

The auxiliaries necessary for the drive train operation in the intend application

shall be installed in the same position as in the vehicle.

Auxiliaries to be removed

Air compressor for brakes, Power steering compressor, Suspension system,

Air conditioner system, etc.

Where accessories cannot be removed, the power they absorb in

the unloaded condition may be determined and added to the measured power.

16

UN No.85 MEASUREMENT OF ENGINE POWER

2. Explanation of test equipment.

The document which should be prepared

By preparing these kind of documents in advance,

the certification test will proceed smoothly.

1

Test motor and controller

2

Auxiliaries (cooling system)

3

Measuring equipment

Model type, ID no. , Serial no.

etc.

Model type, ID no. ,Serial no.

Manufacturer, Inspection date,

Expiration date etc.

17

UN No.85 MEASUREMENT OF ENGINE POWER

2. Explanation of test equipment.

The document which should be prepared

We have submitted a information concerning the conduct of

tests to the certifying officer.

Annex2 and Annex3

Annex 2

Essential characteristics of the electric drive train and information

concerning the conduct of tests

1. General

1.1. Make: .........................

1.2.Type: ...........................

1.5 Test Voltage: ………….

----2. Motor

2.1. Working principle

2.1.1. Direct current (DC)/alternative current (AC)1 number of phases: ………

2.1.5. Number of poles of the motor: .............

----3. Motor controller

4. Cooling system

18

UN No.85 MEASUREMENT OF ENGINE POWER

2. Explanation of test equipment.

Accuracy of measurements

DC Voltage source : Maximum voltage drop is 5%.

periods of less than 10sec, excluded.

Torque : +/-1% of measurement torque.

The accuracy in the lower half of the measuring

range of the dynamometer bench may be +/-2%

of measured torque.

Motor speed : 0.5% of measured speed.

Motor inlet air temp. : +/-2K

19

UN No.85 MEASUREMENT OF ENGINE POWER

3. Explanation of the certification test method.

The certification test in a UN No.85 regulation require

only the NET power test to a internal combustion engine.

However, the test of an electric motor require the following two data.

1. Determination of the NET power.

2. Determination of the maximum 30minutes power.

20

UN No.85 MEASUREMENT OF ENGINE POWER

3. Explanation of the certification test method.

Outline of the determination of the NET power

1. Measure the maximum power of a full motor load.

This test shall consist of a run at full setting of the power controller.

2. Measurements shall be taken with a sufficient number of motor speed points to define the power curve correctly

between zero and the highest motor speed.

3. Whole test shall be completed within 5minutes.

4. The application value of the power should not have a difference over +/‐2% to a measurement value. 5. Just before beginning the test, the motor shall be run on the bench

for three minutes delivering a power equal to 80% of the maximum power at the speed recommended by the manufacture.

21

UN No.85 MEASUREMENT OF ENGINE POWER

3. Explanation of the certification test method.

Warm up of a motor before the NET power test

Just before NET measurement, it needs to be warmed up will 80%

of the maximum output for 3 minutes.

This output characteristic is the PMSM

permanent magnet synchronous motor. Maximum power

80% of the

max, power

Motor Speed

Input Voltage

Shaft Power = 80%of max, power

Measurable power

and speed range

Shaft Torque

3min.

22

UN No.85 MEASUREMENT OF ENGINE POWER

3. Explanation of the certification test method.

Data of 3minutes warm-up

3 minutes

23

UN No.85 MEASUREMENT OF ENGINE POWER

3. Explanation of the certification test method.

Determination of the NET power

The item of the data which should be measured.

The shaft power value is calculated in the following formula.

P

2∗ ∗ ∗

60 ∗ 1000

P : Shaft power [kW]

N : Motor revolution speed[min-1 (rpm)]

T : Torque[Nm]

π : Circle ratio (The ratio of the circumference of a circle to its diameter)

Therefore, motor speed and torque are measured.

And voltage is also measured in order to prove that

the value has not changed.

24

UN No.85 MEASUREMENT OF ENGINE POWER

3. Explanation of the certification test method.

Determination of the NET power

In order to record the voltage and the rotational speed and the torque,

we will prepare tables and graphs like this when measuring the NET.

2.Examination table

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

Torque

Shaft Power

Input Voltage

Nm

200.5

200.2

200.1

200.0

199.6

199.5

191.6

176.8

164.5

144.0

128.4

115.3

96.3

82.3

71.4

63.8

61.9

36.5

1.0

kW

2.1

10.5

20.9

41.9

52.3

57.5

60.2

60.2

60.3

60.3

60.5

60.4

60.5

60.3

59.8

60.1

60.0

36.4

1.0

V(DC)

300.2

300.2

300.1

300.2

300.2

300.1

300.1

300.2

300.2

300.1

300.1

300.2

300.1

300.1

300.1

300.1

300.1

300.2

300.2

80

240

Shaft Power

Shaft Power (kW)

No.

Revolution

Speed

min - 1

100.1

500.1

999.7

1999.9

2500.1

2750.0

3000.0

3250.2

3500.1

3999.9

4499.7

5000.4

6000.2

6999.9

8000.1

9000.0

9250.1

9500.2

9750.4

Torque

70

210

60

180

50

150

40

120

30

90

20

60

10

30

0

0

1000

2000

3000

4000

5000

6000

7000

8000

Torque (Nm)

Motor controller

Electric motor

Target

Speed

min - 1

100

500

1000

2000

2500

2750

3000

3250

3500

4000

4500

5000

6000

7000

8000

9000

9250

9500

9750

0

9000 10000

Revolution Speed (min-1)

25

UN No.85 MEASUREMENT OF ENGINE POWER

3. Explanation of the certification test method.

Determination of the target speed for NET power test

2. Measurements shall be taken with a sufficient number of

motor speed points to define a power curve correctly

between zero and the highest motor speed.

→ A sufficient number of target motor speed needs to be decided.

2.Examination table

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

Motor controller

Torque

Shaft Power

Input Voltage

Nm

200.5

200.2

200.1

200.0

199.6

199.5

191.6

176.8

164.5

144.0

128.4

115.3

96.3

82.3

71.4

63.8

61.9

36.5

1.0

kW

2.1

10.5

20.9

41.9

52.3

57.5

60.2

60.2

60.3

60.3

60.5

60.4

60.5

60.3

59.8

60.1

60.0

36.4

1.0

V(DC)

300.2

300.2

300.1

300.2

300.2

300.1

300.1

300.2

300.2

300.1

300.1

300.2

300.1

300.1

300.1

300.1

300.1

300.2

300.2

240

80

Shaft Power

70

Shaft Power (kW)

No.

Revolution

Speed

min - 1

100.1

500.1

999.7

1999.9

2500.1

2750.0

3000.0

3250.2

3500.1

3999.9

4499.7

5000.4

6000.2

6999.9

8000.1

9000.0

9250.1

9500.2

9750.4

Torque

210

60

180

50

150

40

120

30

90

20

60

This power characteristic is the PM synchronous motor. 10

0

0

1000

2000

3000

4000

5000

6000

7000

8000

30

0

9000 10000

Revolution Speed (min-1)

Note : Above data is an example .

26

Torque (Nm)

Electric motor

Target

Speed

min - 1

100

500

1000

2000

2500

2750

3000

3250

3500

4000

4500

5000

6000

7000

8000

9000

9250

9500

9750

UN No.85 MEASUREMENT OF ENGINE POWER

3. Explanation of the certification test method.

Determination of the NET power

Actual speed and the maximum torque are measured at each target speed.

Then a shaft power is calculated by multiplying the speed and the torque .

2.Examination table

Electric motor

Motor controller

120

330

Torque

Shaft Power

Input Voltage

110

Nm

300.3

300.2

300.1

300.1

300.1

299.0

278.3

255.7

219.1

191.7

170.8

153.5

128.1

109.5

95.3

85.0

51.6

26.5

1.0

kW

3.1

15.7

31.4

47.1

62.8

78.3

80.1

80.3

80.3

80.3

80.5

80.4

80.5

80.3

79.8

80.1

50.0

26.4

1.0

V(DC)

250.1

250.0

250.1

250.2

250.2

250.3

250.1

250.1

250.2

250.1

250.1

250.2

250.1

250.1

250.2

250.1

250.1

250.2

250.3

100

300

90

270

80

240

70

210

60

180

50

150

40

120

30

90

20

60

10

30

Note : Above data is an example .

Shaft Power

Torque

Torque (Nm)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

Revolution

Speed

min - 1

100.1

500.1

999.7

1500.1

1999.9

2500.1

2750.0

3000.0

3500.1

3999.9

4499.7

5000.4

6000.2

6999.9

8000.1

9000.0

9250.1

9500.2

9750.4

Shaft power (kW)

No.

Target

Speed

min - 1

100

500

1000

1500

2000

2500

2750

3000

3500

4000

4500

5000

6000

7000

8000

9000

9250

9500

9750

0

0

0

1000 2000 3000 4000 5000 6000 7000 8000 9000 10000

Revolution Speed (min-1)

In the case of the PM

Synchronous Motor

27

UN No.85 MEASUREMENT OF ENGINE POWER

3. Explanation of the certification test method.

Determination of the NET power

Other controlled motor

Maximum Power In the case of the PM

Synchronous Motor

28

UN No.85 MEASUREMENT OF ENGINE POWER

3. Explanation of the certification test method.

Determination of the NET power

Other types motor

Maximum Power

In the case of the Induction Motor

29

UN No.85 MEASUREMENT OF ENGINE POWER

3. Explanation of the certification test method.

Outline of the Maximum 30 min. power test

1. The maximum power value that can be outputted by continuation for 30 minutes.

2. The electric drive train shall run at the bench at a power which is the best estimate of the manufacturer for the maximum 30 minutes power.

3. The speed must be in a speed range, which the NET power

is greater than 90% of the maximum power.

This speed shall be recommended by the manufacture.

4. The power must be in a range of +/‐5% of the power value at the start of this test.

5. The application value of the power should not have a difference over +/‐2% to a measurement value. 30

UN No.85 MEASUREMENT OF ENGINE POWER

3. Explanation of the certification test method.

Determination of the measurement point

90% of

max. power

Maximum power

Measurable area

NET

power

In the case of the Permanent Magnet

Synchronous Motor

31

UN No.85 MEASUREMENT OF ENGINE POWER

3. Explanation of the certification test method.

Determination of the measurement point

Temperature rise of the coil due to the current.

Upper limit of the motor coil temp.

Motor coil temp.

motor speed

torque

power

32

UN No.85 MEASUREMENT OF ENGINE POWER

3. Explanation of the certification test method.

Determination of the measurement point

Example of when the applied torque is too large.

motor coil temp.

Upper limit of the motor coil temp.

motor speed

Overrun

torque

power

NG

Over +/-5%

30min.

33

UN No.85 MEASUREMENT OF ENGINE POWER

3. Explanation of the certification test method.

Determination of the measurement power, so that the motor coil

temp. does not exceed the upper limit.

Higher coil temp.

rise

Upper limit of the motor coil temp.

Coil temp.

of each power

Higher power

(Larger torque)

Each power

34

UN No.85 MEASUREMENT OF ENGINE POWER

3. Explanation of the certification test method.

Determination of the measurement point

Examples of items to limit the motor torque

1. Motor coil temp.

The purpose of having many coils inside the motor is to excite magnetic field,

therefore the coil will heat up when applying high current.

Copper wire that make up the coil is divided into insulation class in the

table below.

2. Temp. of Insulated Gate Bipolar Transistor(IGBT) in Controller

Same as IGBT inside motor controller, high current flows will generate

heat too. Normally, the upper limit temperature is set by the transistor maker.

Thus, temperature limit are set on motor and controller, respectively.

If this limit starts, the torque of motor will be reduced, in order to lower

the temperature.

IEC 60085

Thermal class(℃)

90

105

120

130

155

180

200

220

250

35

UN No.85 MEASUREMENT OF ENGINE POWER

3. Explanation of the certification test method.

Maximum 30min. power test sheet. (example)

In order to record the voltage and the rotational speed and the torque,

We will prepare tables and graphs like this when measuring the Maximum

30minutes power.

2.Examination table

( hr :min :sec )

min-1

1

Start

2

05min. later

3

10min. later

4

15min. later

5

20min. later

6

25min. later

7

30min. later

Average (7points)

Torque

Input

Voltage

Nm

kW

V(DC)

90

30

25

Shaft output power (kW)

Time

No.

Motor controller

Shaft

Power

60

20

Torque (Nm)

Electric motor

Revolution

Speed

15

30

10

Shaft

Power

5

Torque

0

0

Start

05min.

later

10min.

later

15min.

later

20min.

later