Molding and Casting Products in Plastic Injection Molding-for imoldmaking.com

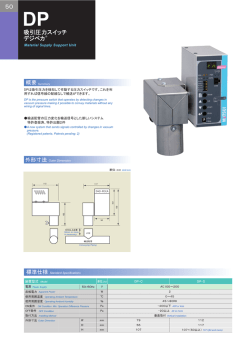

Molding and Casting Products in Plastic Injection Molding www.imoldmaking.com Molding and Casting Products in Plastic Injection Molding Die casting, as it is generally understood, is a process for producing engineered metal parts. The process contains forcing molten metal under high force into steel dies or molds that are reusable. These diets can be designed to generate complex shapes with a stunning accuracy as well as repeatability. This process is preferred by many industries today because of some its benefits over plastic molding. It can be said that it generates powerful and more durable parts with closer tolerances. Additional, die cast parts have bigger resistance to high temperature and posses superior automatic properties. This procedure constitutes injecting molten plastic under top force into a mold or die. Die casting machines are generally rated in clamping tons, indicating the quantum of force they are able of exerting on the die. There are 2 types of machines are their only general difference is the methods used to inject molten plastic into a die - one has a warm chamber and the other a chill chamber. A full cycle can change from less than one second to 3 minutes depending on the size of the wanted product. This makes it the quickest method for producing precise plastic or nonferrous metal parts. Injection molds China | Injection molding China It needs to be stated it is an economical, well-organized process providing a broader range of components and shapes than any other producing technique. The key benefits can be summarized as: high speed production capability/ hard shapes within close tolerance limits/ promised dimensional stability and accuracy/ finished products are warm resistant and sturdier than plastic injection molding of equal dimensions/ multiple finishing methods / end products can be simply plated or finished. As regards it can be said that die casting procedure sturdier, more durable parts with nearer tolerances. The construction of casting dies is almost the same to that of molds for injection molding. Die cast parts have bigger resistance to great temperature and posses superior electrical properties. Matched with plastic injection molding, die casting excellent help stop radio frequency and electromagnetic emissions. For chrome plating, die castings are much more well-matched than plastics. Custom Injection molding China | Mold Making China There is no denying the science and art of transforming plastic resins into helpful products or parts has had a wonderful impact on industrial and commercial spheres. Injection molds can be pretty costly but if wanted part quantity is bigger, the mold cost will become affordable in the long run. Some molds are definitely made with different cavities, these multicavity mold leads to increase production competence and the cost per part are very much minimized.

© Copyright 2026